THE TRIMAX STORY.

Our approach to innovation is driven by you. With a focus on creating solutions to customer challenges, together, we’re able to raise the bar on results.

EQUIPMENT SHOULD NEVER BE A BARRIER TO SUCCESS.

From humble beginnings in New Zealand to a world leader in Commercial Mowing – our success is driven by our passion to help customers find a better way.

We listen to how you use our products, designing with customer-focused innovation to solve problems you encounter. The result? Mowing solutions which increase productivity, reduce maintenance and can be relied on day-after-day, for years of full-time commercial use.

Originating in the Bay of Plenty, New Zealand in the 1980’s, Trimax Mowers were originally developed for the booming New Zealand Kiwifruit industry. But demand soon grew from groundsmen and turf managers who had heard of the mowers’ reputation for durability, quality of cut and low maintenance.

Today Trimax designs and manufactures a wide range of rotary and flail equipment, which has become the benchmark worldwide. From England’s Windsor Castle to US PGA Championship courses, we’re continuing to raise the bar on results.

Equipment that powers performance.

LOW TOTAL-COST-OF-OWNERSHIP.

Renowned for low maintenance and long commercial life, Trimax mowers pay for themselves many times over. With low hp requirements, minimal moving components, reduced greasing and affordable parts, Trimax is the smart investment choice.

LONG COMMERCIAL LIFE.

Designed for fulltime commercial use and strength tested for up to 10 years, our equipment lasts. We back that up with an industry leading 3 year warranty. We’re still providing parts support to Trimax models which have been in the field 30 years and counting!

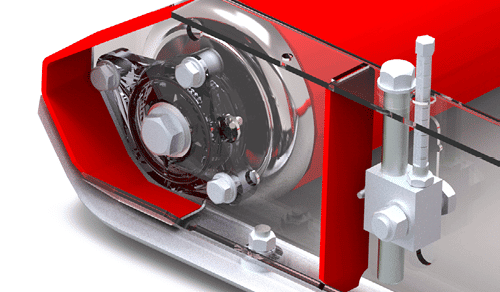

EASE OF MAINTENANCE.

With features such as maintenance free spindles, sealed for life bearings, grease free bushes and automatic belt tensioners, our service maintenance is designed to be quick… Enabling you to spend more time on the things you love and less time on maintenance!

INTUITIVE TO USE.

Simplicity is key! That’s why we’ve designed all Trimax mowers to be easy to operate. By avoiding unnecessary and complicated systems, operators have more time to focus on output and new users can enjoy a stress free experience.

INDUSTRY LEADING CUT PRESENTATION.

Our cut innovation is developed through a robust scientific process and validated with extensive in-market trials, it’s not just left to chance. The result? Optimal performance cutting systems which provide an unrivaled spread and finish.

SERVICE THAT EXCEEDS EXPECTATION.

The entire Trimax team is dedicated to providing our customers, dealers and operators with the best service possible. With highly trained staff and service centers in all markets of operation, you’ll get the right advice and support first time.

28 Years of UK History.

Since entering the UK market back in 1998, the Trimax brand has grown at lightning speed. Thanks to a carefully crafted dealer network and a customer-focused philosophy, we’re proud that almost every UK council now operates a Trimax mower.

To help service our growing community, we purchased a new UK facility in 2015, and focused our efforts on local manufacture. We now have some fantastic suppliers which have enabled us to manufacture 75% of our range right here in the UK.

Dedicated to providing one of the best customer service models in the industry, we have committed to holding over £1.1m worth of spare parts in the UK at any one time. Maximum uptime, everytime.

Today Trimax has manufacturing facilities in New Zealand, Australia, United Kingdom and the United States. With over 33,000 mower decks sold worldwide, Trimax is now a global leader in commercial mowing systems.

OUR INDUSTRY PARTNERS –

“During our 28 years in the UK market, we’ve established an extensive dealer network to support our customers throughout their Trimax journey. Our deep understanding of local conditions and valuable customer insights have enabled us to design and engineer products which meet the demanding conditions of the UK market.”

– RIKKI BOWN

Trimax Mowing Systems Southern Area Sales Manager

Our History.

First production

1981First production of Ezeemow, Mowcraft & Mulchmasta flail mowers.

Production continues

1983Pride, ProCut and Ezeemow disc mowers & the ProCut S1 rotary.

First exports

1985First exports to Australia and a dedicated research and development department established.

New mowers released

1989Warlord and Sidewinder were released.

Stealth S1 released

1991Stealth S1 released.

Exporting to the UK

1992First exports to Great Britain & awarded 'NZ Exporter of the Year.

Topper S1 released

1993Topper S1 released & awarded 'NZ Exporter of the Year'.

Exporting to the USA

1995First exports to the United States.

Windsor Castle mows with Trimax

1997Windsor Castle and surrounding grounds start using the Trimax ProCut for their maintenance.

Trimax UK opens

1998Trimax distribution warehouse opened in Great Britain.

Pegasus S1 released

2001The Pegasus S1 is released. First Rotary roller mower in the USA.

LazerBladez™ released

2004Trimax LazerBladez™ released.

Trimax USA opens

2005Set up of USA office in Atlanta, Georgia.

Quattro Blades released

2008Trimax Quattro Blades and X-WAM released.

Merlin released

2010Merlin dedicated golf and turf mower released.

30th Anniversary

201130th Anniversary of Trimax.

Trimax AUS opens

2013Set up of Australian office in Melbourne.

Trimax Snake released

2014Trimax Snake is released. A fully dedicated sports turf and golf mower.

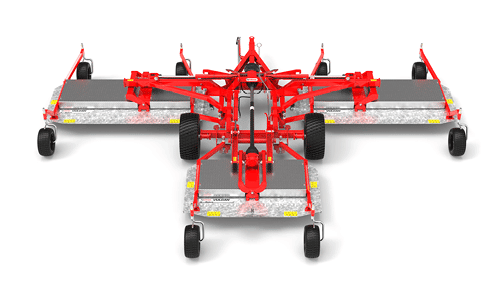

Stealth S3 released

2016The Stealth S3 is released. A new wing mower for sports and recreation mowing.

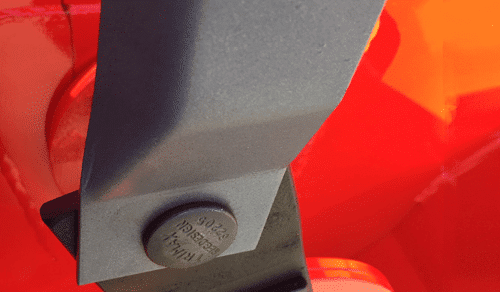

Release of LocTEK

2018Release of LocTEK, Trimax's Stubless Roller Retention System.

New innovation

2019Trimax Castor Wheel Mower to be released for turf and cool season grasses.