Trimax Celebrates Its 40th Anniversary

In 2021, Trimax Mowing Systems is celebrating our 40th anniversary – that’s 40 years of innovation, service, and leadership in commercial mowing solutions.

Where has the time gone?

In the last 40 years, Trimax has grown from a seven-person workshop into an international success story .

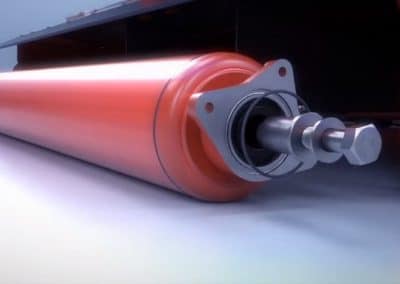

Innovation has been at the very heart of the company since it was founded by Bob Sievwright in 1981. He was looking for a way to share his revolutionary Gamma Flail design, the first high-efficiency flail available on the market. Trimax was formed from an amalgamation of local flail mower manufacturers and, with the implementation of the Gamma Flail, quickly became a mowing solutions leader in the burgeoning kiwifruit industry in New Zealand’s Bay of Plenty.

In 1983 Trimax joined forces with Procut Engineering, founded by Jim McEwen, to market their low-profile rotary mowers and in 1985 purchased the company to round out the Trimax product line. With both flail and rotary mowers in their range, Trimax was ready to grow and expand into new markets.

Today Trimax operates facilities and teams in New Zealand, Australia, the United States, and the United Kingdom. Our flail and rotary mowers can be found maintaining turf to a high standard around the world.

Celebrate with us!

40 years of operation is quite an achievement, and we’re proud to mark this anniversary together as a global team with our Trimax family of dealers and customers.

Throughout the year we’ll share stories and insights from Trimax team members who have been with the business from the beginning. We’re excited to show you how far we’ve come and to share some exclusive previews of what’s up ahead for Trimax.

We invite you to join us as we look back on our history and as we look forward to what the next 40 years will bring. You’ll see we’ve still got some surprises up our sleeves – follow us on social media to join the celebration!