Trimax Mowing Systems gab bekannt, dass das Unternehmen sich vom wartungsintensiven Walzenhaltesystem verabschiedet und LocTEK auf den Markt gebracht hat – ein zum Patent angemeldetes wartungsfreies Walzenhaltesystem, das es nur bei Trimax gibt.

Die Hauptvorteile von LocTEK gegenüber dem herkömmlichen Walzenhaltesystem sind:

#1 Erheblich höhere Stabilität und Festigkeit: Herkömmliche Walzenhaltesysteme halten die Walzenstummel direkt in den Lagern mit Hilfe von Gewindestiften oder Schließringen. Bei dieser Methode kam es jedoch lange Zeit durch regelmäßige horizontale Belastung zu Verschleißerscheinungen an den Stiften und Lagern und damit zu Problemen beim Halten der Walzen.

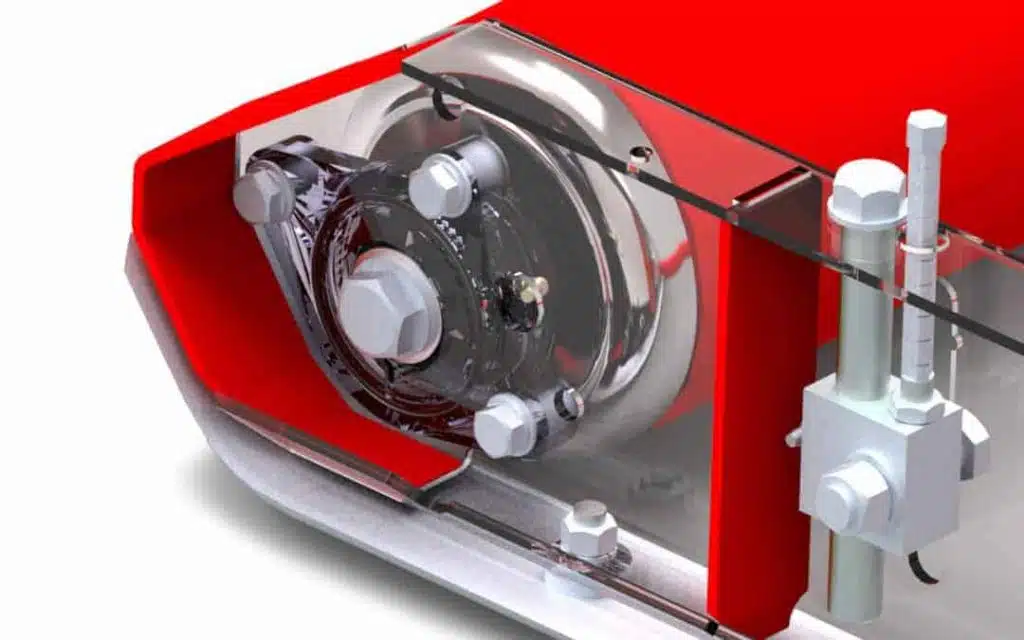

Herkömmliche Walzenstummel müssen oft nachbearbeitet oder ausgetauscht werden, um Verschleißprobleme zu beheben, die sich auf den Halt der Walzen sowie deren Ausrichtung auswirken. LocTEK beseitigt diese Probleme vollständig durch die Verwendung eines besonders belastbaren Gewindebolzens, der durch eine schützende, verzinkte Hülse eingeführt wird und die Walze, das Lager und die Seitenführungen zusammenhält. Dieses einfache, aber innovative Bolzensystem ist nicht nur verschleißfrei, sondern bietet auch eine viel stabilere Halterung und gewährleistet eine kontinuierliche und genaue Ausrichtung der Walzen.

Das neue LocTEK-System beinhaltet auch verstärkte Drei-Schrauben-Lagergehäuse, die mit den Seitenführungen verschraubt werden und das herkömmliche Zwei-Schrauben-System ablöst.

#2 Einfacherer Austausch und geringere Wartungskosten: LocTEK reduziert die benötigte Zeit für den Austausch erheblich. Früher war es oft schwierig und zeitaufwändig, einen mit Kleber befestigten Stummel aus einem Lager zu entfernen. LocTEK erfordert keine Spezialwerkzeuge und kann in nur 15 Minuten ausgetauscht werden. Der Bolzen kann einfach mit einem Schlagbohrer aus dem Walzen- und Lagersystem entfernt werden und die mit Anti-Seize montierte Zinkhülse kann leicht aus dem Lager entfernt werden.

Während bei einigen herkömmlichen Systemen der Walzenstummel nachbearbeitet werden muss oder – wenn der Verschleiß an den Walzenstummeln zu groß ist – eine komplett neue Walze gekauft werden muss, besteht LocTEK aus einzelnen Teilen, die separat erworben werden können. Dies bedeutet, dass nur das entsprechende Teil gekauft werden muss, was zu erheblichen Kosteneinsparungen führt.

#3 Erhöhte Lebensdauer der Lager: Eine der häufigsten Ursachen für Schäden beim Lager ist eine falsche Ausrichtung der Stummel. Eine Falschausrichtung der Walzenstummel kann dazu führen, dass der äußere Laufring des Lagers im Gehäuse schwingt, was einen vorzeitigen Verschleiß des Lagers und des Lagergehäuses sowie ein höheres Austauschintervall zur Folge hat. Durch die vollständige Beseitigung einer Falschausrichtung werden die LocTEK-Lager weniger belastet und halten dadurch deutlich länger. LocTEK verwendet außerdem marktbewährte, qualitativ hochwertige Lager, die jahrelang von Trimax im Gelände getestet wurden.

Um die Langlebigkeit der Lager weiter zu unterstützen, bietet LocTEK mit Hilfe einer cleveren konvexen Rippe am Ende der LocTEK-Walzen einen neuen zusätzlichen Schutz gegen Wasserschäden. Der Walzenrand verhindert, dass Wasser an einer vertikalen Walze hinunterlaufen und das Lager erreichen oder sich dort ansammeln kann.

LocTEK wird derzeit bei allen neuen Trimax Pegasus und ProCut S4 Mähern eingebaut und kann auch als Nachrüstsystem erworben werden, das für bestimmte Mäher zur Umrüstung der Walzenhaltesysteme entwickelt wurde. Für weitere Informationen über das neue LocTEK-System oder für eine kostenlose Vorführung kontaktieren Sie bitte Trimax unter +44 (0) 1933 652235.

New Zealand Pat. App. 737217

Australian Pat. App. 2016250934

UK Pat. App. 1718763.4

US Pat. App. 15/567,875