Jeder gibt die maximale Drehzahl der Messer an, wobei diese nicht annähernd so wichtig wie die Drehzahl der Spindel ist.

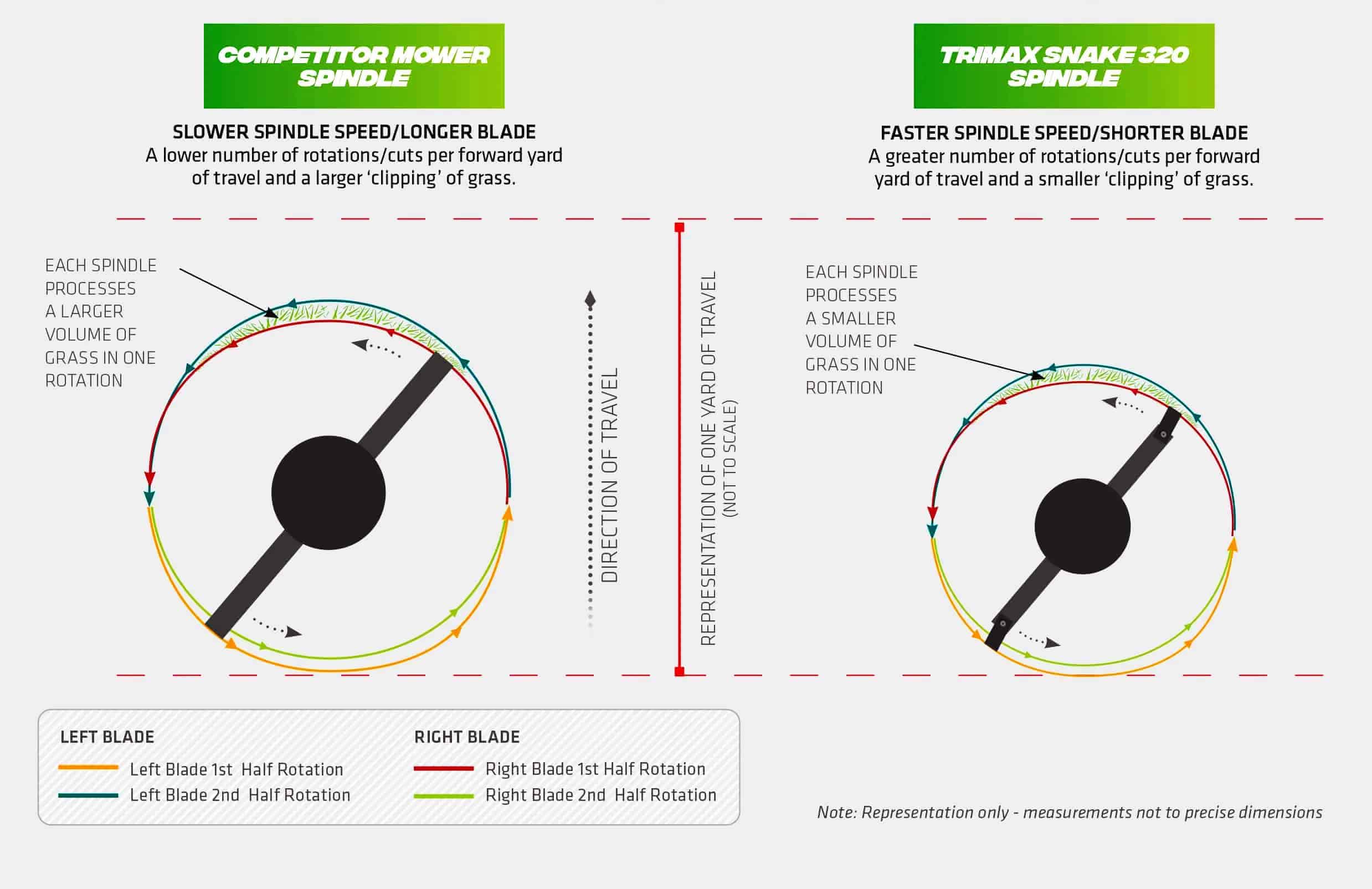

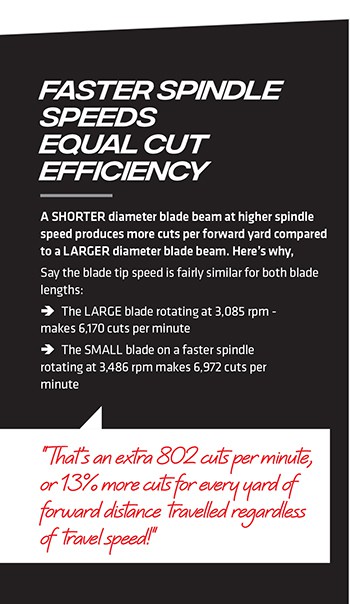

Die maximale Drehzahl der Messer ist bei allen Marken ähnlich, und einige Marken weisen höhere Spitzengeschwindigkeiten als erforderlich auf, da der sauberste Schnitt nur innerhalb eines bestimmten Geschwindigkeitsbereichs möglich ist. Ist die Geschwindigkeit zu schnell, werden Kraft und Treibstoff verschwendet, und ist sie zu langsam, werden die Grashalme ausgerissen oder beschädigt. Was wirklich zählt, ist, wie viele Schnitte oder Umdrehungen das Messer pro gefahrenem Meter absolviert – und hier kommt die Spindelgeschwindigkeit ins Spiel.

Die Trimax-Mäher verfügen über kürzere Messerbalken, die es ermöglichen, mehr Spindeln für eine gegebene Schnittbreite bei den Mähdecks zu montieren. Dadurch bleibt das Mähdeck kompakt, was zu einer besseren Gewichtsverteilung und Manövrierfähigkeit führt.

Um die perfekte Geschwindigkeit für sauber geschnittenes Gras beizubehalten, drehen sich diese kürzeren Messerbalken mit einer höheren Geschwindigkeit, sodass das Messer bei jeder Umdrehung einen kleineren Teil des Grases abschneiden kann – was letztendlich die Anzahl der Schnitte pro gefahrenem Meter erhöht. Diese erhöhte Anzahl von Schnitten ist für die Erzielung eines feineren Schnitts unerlässlich.

Ein weiterer Vorteil ist, dass jede Spindel nur ein kleines Volumen an Gras verarbeiten muss. Dies ermöglicht die effektivste Nutzung des speziellen Trimax-Luftstromdesigns, bei dem die Vermischung des geschnittenen Grases mit Luft für eine gleichmäßige Verteilung sorgt – sicher und effektiv über die hintere Walze ohne Scheiben.

Um eine noch größere Anzahl von Schnitten pro gefahrenem Meter zu erzielen, bietet Trimax für ausgewählte Modelle das patentierte Quattro Blade Kit an, das die Anzahl der Messer pro Spindel von zwei auf vier erhöht und damit die Anzahl der Schnitte pro Umdrehung verdoppelt.

Quattro kann optional nachgerüstet werden, wenn ein noch feinerer Grasschnitt benötigt wird. Bei allen Anwendungen auf Naturrasen bzw. für einen Feinschnitt empfehlen wir den Einsatz von Quattro-Mähwerken und Messerkombinationen Ihrer Wahl, einschließlich der Verwendung von flachen und gedrehten Klingen.

Sprechen Sie noch heute mit Ihrem Trimax Verkaufsberater über die beste Messerkombination für Ihren Anwendungsbereich. Sie können auch eine Vorführung buchen, indem Sie hier klicken, oder unseren Katalog herunterladen, indem Sie hier klicken.